PRODUCTS

-

100mm wide cutting scrap machine

A cutting scrap machine is a device used to shear metal or non-metal waste (such as leftover materials,waste sheets, pipes, etc.) into specific sizes or shapes. During operation, the waste is placed into the machine's feeding port, and the blades driven by hydraulic or mechanical systems apply shearing force to cut or segment the waste. It is suitable for scenarios like waste recycling stations and metal processing workshops, and can recycle or preprocess waste materials such as steel, aluminum alloy, and plastic to facilitate subsequent transportation, storage, and reuse.

-

Polish Machine

A Polish Machine is primarily used for grinding and polishing the surfaces of materials such as metal, plastic, wood, and stone. By installing polishing wheels (e.g., wool wheels, nylon wheels, grinding wheels) or abrasive discs of different materials, it performs deburring, rust removal, sanding, and gloss treatment on workpiece surfaces. During use, fix the polishing wheel on the main shaft, start the machine, hold the workpiece by hand or fix it with a fixture, make the workpiece surface contact the rotating polishing wheel, and polish evenly with polishing agents (such as polishing wax, grinding paste). It is suitable for surface finishing in industries like hardware, automotive parts, furniture, and jewelry.

-

Vibrating disc

A Vibrating Disc is an automatic orienting and feeding device, mainly used for sorting and conveying small components. During operation, high-frequency vibrations generated by the bottom electromagnet make parts (such as screws, buttons, electronic components) in the hopper move upward along the spiral track. Meanwhile, orienting mechanisms (such as notches, baffles) on the track eliminate parts with incorrect orientations, ensuring parts are discharged in a unified posture and conveyed to subsequent processing stations (e.g., assembly machines, packaging machines). It is widely used in the front end of automated production lines in electronics, hardware, plastics, pharmaceuticals, and other industries.

-

Polish Machine

A Polish Machine is primarily used for grinding and polishing the surfaces of materials such as metal, plastic, wood, and stone. By installing polishing wheels (e.g., wool wheels, nylon wheels, grinding wheels) or abrasive discs of different materials, it performs deburring, rust removal, sanding, and gloss treatment on workpiece surfaces. During use, fix the polishing wheel on the main shaft, start the machine, hold the workpiece by hand or fix it with a fixture, make the workpiece surface contact the rotating polishing wheel, and polish evenly with polishing agents (such as polishing wax, grinding paste). It is suitable for surface finishing in industries like hardware, automotive parts, furniture, and jewelry.

-

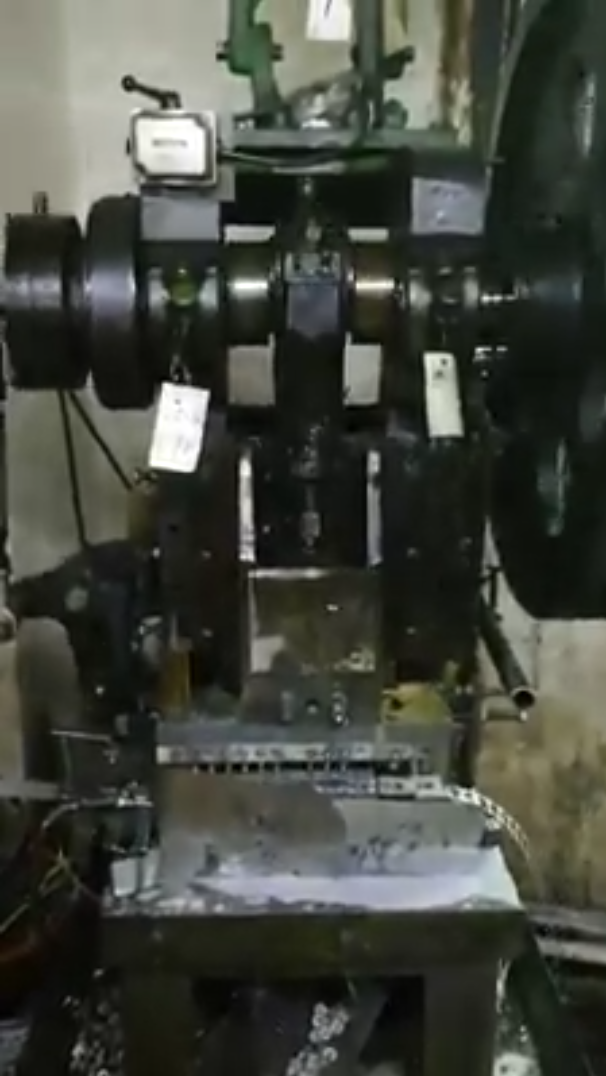

punch machine 16ton

A punch machine is a stamping equipment that applies pressure to metal or non-metal sheets through a die, causing plastic deformation or separation to process them into parts of specific shapes. During operation, the sheet is placed on the punch's worktable, the die is fixed, and the punch head presses down via hydraulic or mechanical transmission to complete processes like punching, blanking, bending, and stretching.

-

9mm Stainless Steel Rivet Assembly Machine

-

polish machine

-

packing machine

-

Dryer machine