PRODUCTS

-

Packing Machine

Pour buttons,nail into the vibrating plate or feeding device. The machine automatically completes sorting, metering, bag-making, filling, sealing, cutting, and counting. Parameters like quantity and bag length can be set. It supports three-side sealing or back sealing (back sealing is recommended to prevent jamming). The machine detects empty bags or material shortages and stops automatically when the vibrating plate is empty.

-

Dryer Machine

A Dryer Machine is mainly used to remove moisture or solvents from materials through heat conduction, convection, or radiation. During operation, place materials to be dried into the drying chamber, set parameters like temperature (typically 30-200℃), humidity, and time, then start the equipment. The hot air circulation system allows uniform hot air to flow over the material surface, with evaporated moisture discharged through the dehumidification outlet. Different dryer types can be selected based on material characteristics: drum dryers for granular materials, chamber dryers for batch small parts, and heat pump dryers for heat-sensitive materials.

-

Activity button bottom part making machine

The Activity Button Bottom Part Making Machine is used to produce button bottom components with movable structures (such as rotatable shanks, elastic connecting bases). First, metal wires (e.g., copper, stainless steel) are fed into the forming mold via the feeding mechanism. The machine automatically cuts, bends, and stamps the wires to form the basic frame of the movable shank, then installs elastic elements (such as springs, shrapnel) and limit parts, fixing them by riveting or snapping to assemble movable bottom parts that can flexibly open/close or rotate. It is suitable for producing apparel accessories like suit buttons and trench coat buttons requiring movable connections, and can interface with subsequent button assembly lines.

-

Fully Automatic Polish Machine

The Fully Automatic Polish Machine is used for surface polishing of workpieces made of metal, plastic, stone, etc. First, load the workpieces to be polished (such as buttons, hardware parts, decorations) into special fixtures or tanks, and transport them to the polishing area via a conveyor belt. The machine automatically starts multiple polishing wheels (or sand belts, grinding discs) to sand, grind, and mirror-polish the workpiece surface according to preset parameters (rotation speed, pressure, polishing agent dosage). It is suitable for batch processing of regular or special-shaped workpieces, completing processes like deburring, rust removal, and brightening.

-

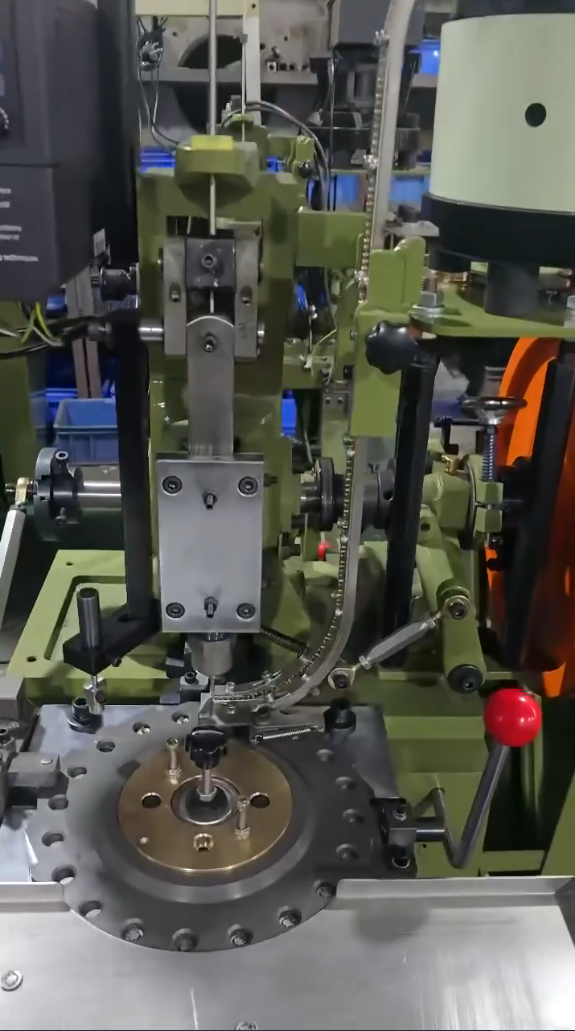

3 in 1 Button Plastic and Metal Assembly Machine

The 3 in 1 Button Plastic and Metal Assembly Machine (Pressing Type) is used to integrate and assemble three components—plastic parts, metal components (such as shanks, bases), and decorative layers—via pressing technology. First, load the three materials into respective vibratory bowls/feeding devices, which sort and transport them to the assembly station. The machine positions the components with precision molds and applies pressure to press them into a complete button through snapping, nesting, or hot-melting (depending on materials). It is suitable for producing composite buttons (e.g., plastic cap + metal base + decorative plate) for mass manufacturing in apparel and luggage industries.

-

Cap Making Machine

A Cap Making Machine is used to process the surface components of buttons (such as caps, decorative layers, etc.). First, prepare the button face materials (like resin, metal sheets, fabrics, etc.) according to specifications, and transport them to the forming station via the feeding device. The machine uses molds, heating (if shaping is needed), stamping and other processes to process the face materials into the cap shape (e.g., round, square, with patterns/LOGOs, etc.) as designed for the buttons. It provides formed face materials for the subsequent overall assembly of buttons (combining with back components), suitable for manufacturing the surfaces of various buttons (such as shirt buttons, jeans buttons).

-

2 in 1 Button Back Part Assembly Machine

The 2 in 1 Button Back Part Assembly Machine is used for the automatic integration of different components (such as metal feet, plastic bases, etc.) at the bottom of buttons. First, place the raw materials of the two types of bottom components in corresponding vibratory bowls/feeding devices. After sorting and conveying, they are accurately sent to the assembly station. The machine grabs and aligns them with robotic arms/fixtures, and combines processes like pressing, snapping, or welding (depending on the button type) to firmly assemble the two components into a complete button back part, connecting to the subsequent overall button production process, suitable for button manufacturing in clothing, bag industries, etc.

-

2 in 1 Light assembly machine

The 2 in 1 Light Assembly Machine is used to automatically feed, accurately align, and assemble two types of small parts (such as electronic components, small hardware, etc.) into finished products according to preset programs. Put the parts to be assembled into corresponding bins separately. The machine sorts and conveys them via vibratory bowls or feeding rails, grabs and positions them with robotic arms or fixtures, and combines heating (if needed), crimping and other processes to quickly assemble different parts into finished products.

-

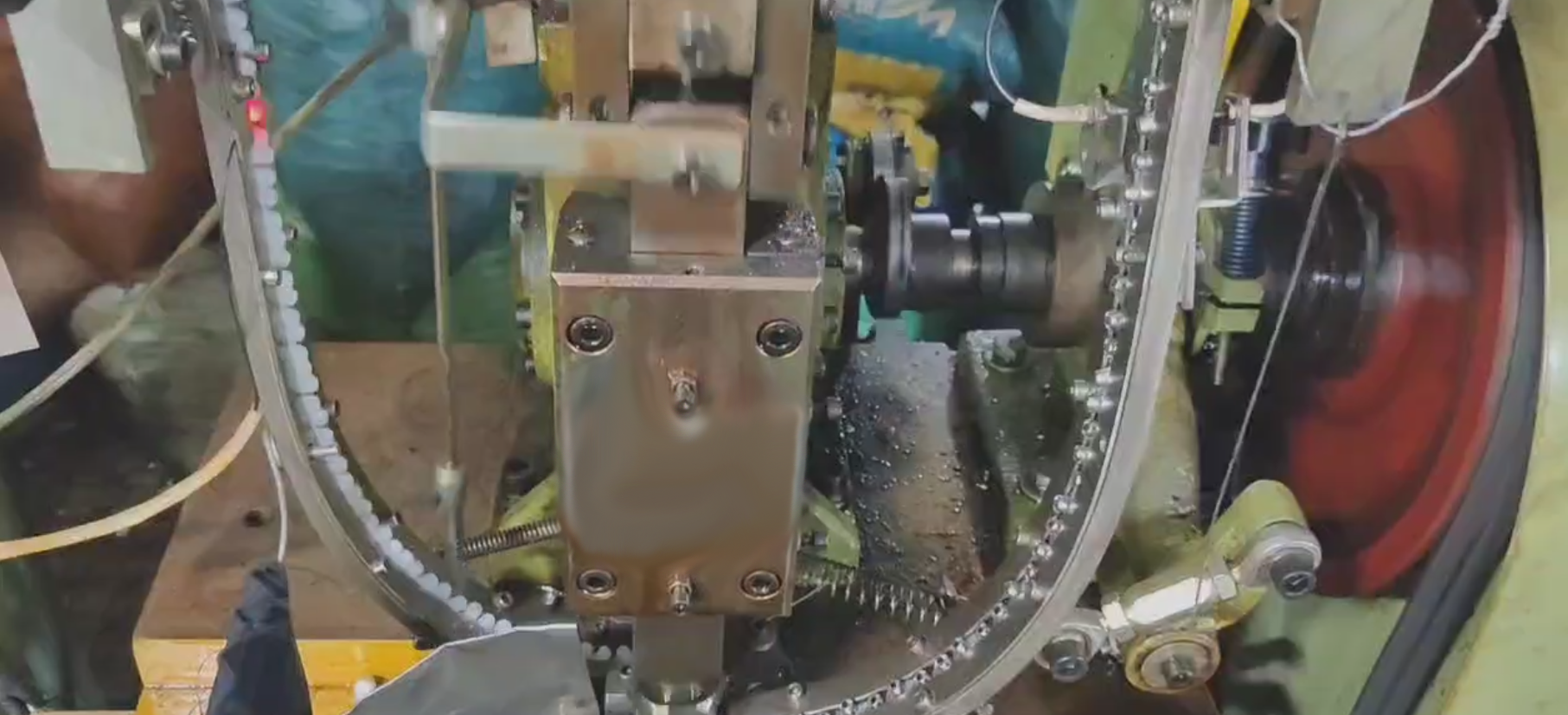

2 in 1 Button Plastic and Metal Assembly Machine(Hot Machine and Stainless Steel Jeans Button Assembly Machine )

The 2 in 1 Button Plastic and Metal Assembly Machine (Hot Type) is used for automatic assembly of plastic and metal buttons (such as jeans buttons). First, place plastic and metal button components in corresponding vibratory bowls. After vibrating and sorting, the feeding mechanism accurately transports them to the assembly station. The heating system heats components (like metal button feet) as needed. Then, through the pressing mechanism, following the set program and pressure, plastic and metal parts are firmly assembled into complete buttons, suitable for button processing in clothing, bag industries, etc.