产品

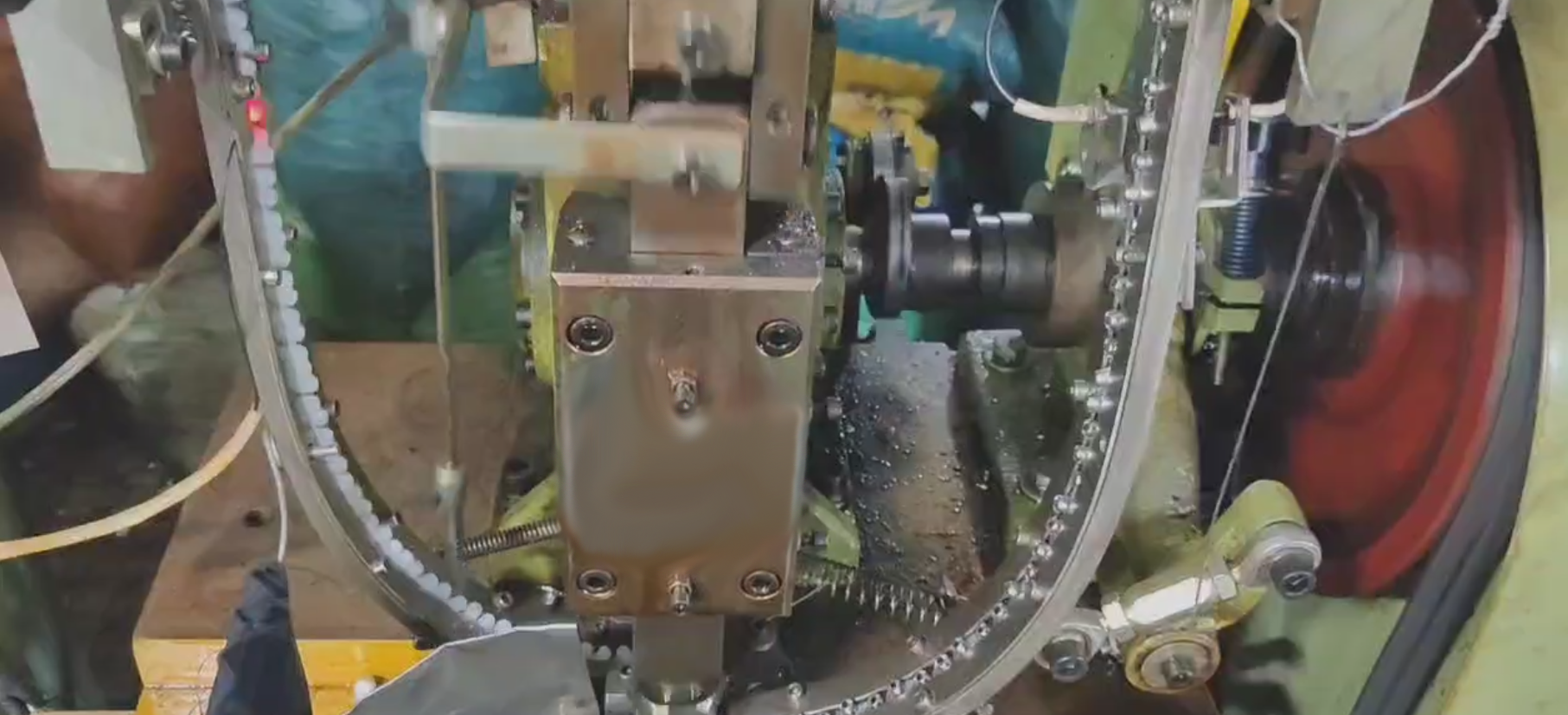

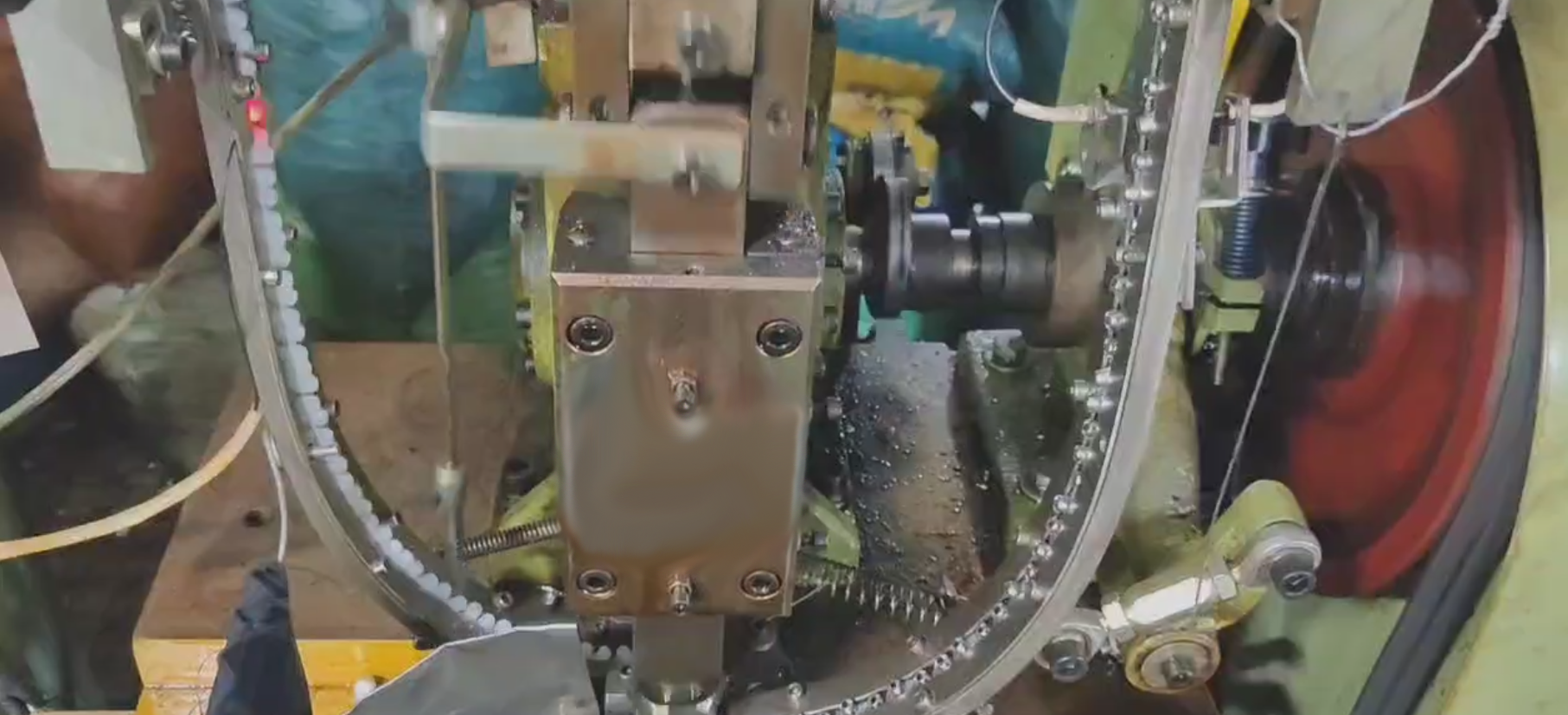

二合一纽扣背板零件组装机

警告:foreach() 函数提供的参数无效 /www/wwwroot/qcgac.com/wp-content/themes/SNKJ/single/single-grid.php 在线的 196

产品结构

高效集成:“二合一”设计可一次性组装两种类型的底部组件,省去了人工逐步操作,大大提高了纽扣背板零件的生产节奏,适合批量生产。.

精准稳定:依靠精密机械结构和传感器的配合,确保零部件的对准和装配精度,减少人为误差,提高后部零件的一致性和良率。.

灵活适应:通过更换模具和调整参数,可与各种纽扣背板组件(不同尺寸和材料组合)兼容,满足多样化的订单要求。.

经济高效:自动化取代了繁琐的手工组装,减少了劳动力投入;机器的一体化设计压缩了流程,降低了生产和运营成本,缩短了交货周期。.