Die-coast Cap Make

- button machine

Die casting machine, 160 tons is the best. The die-cast button cap has no burrs and the surface is more shiny and smooth.

- button mold

3.Things to note

A good mold is the most important factor in ensuring the product. A good mold can not only accurately ensure the size and thickness of the product, but also make the buttons burr-free.At present, the molds in Wenzhou, China are the best.

Die-coast Button Shank

- Button shank machine

The punch press is the most common light industrial machine, and buttons with a capacity of 16-30 tons are the choice of most factories.

- Things to note

The bottom part of a button is an important part of a complete button. In addition to different sizes and thicknesses, the bottom parts used for stainless steel and die-cast buttons are also different.Die-cast caps have rounded corners, but caps made of materials such as stainless steel and iron require cornerless shanks.

Die-coast Button Button Polish & Plating

Die-coast Button Assemble

Assembly of zinc alloy requires more powerful machines.

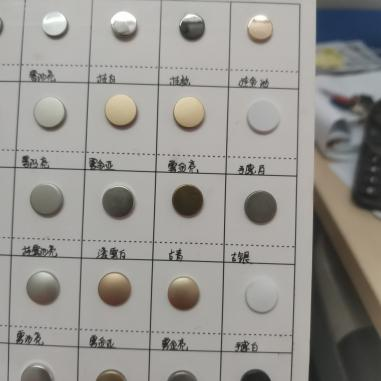

Die-coast Button Finished

- Finished Button