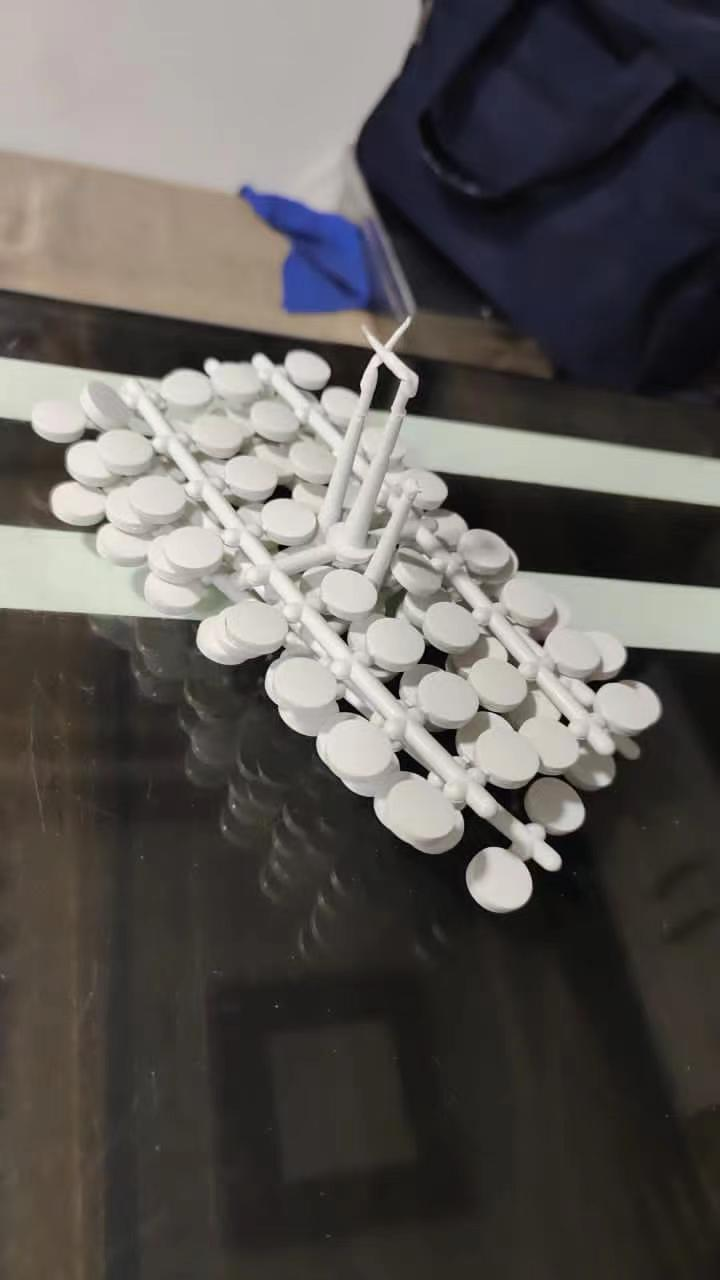

Nylon Cap Make

- button machine

- button mold

3.Things to note

A good mold is the most important factor in ensuring the product. A good mold can not only accurately ensure the size and thickness of the product, but also make the buttons burr-free.

Nylon Cap Separation

- button machine

- Things to note

The current separation methods rely on manual cutting and separation of buttons and frames; the second is nozzle separation and laser separation machines. The cost of laser separation is too high, so most factories use nozzle separation machines. The advantages of the nozzle separation machine are that it is cheap, small in size and fast, but its disadvantage is that it is very dependent on the mold. If the mold is too poor and the separation point is too far from the button, the button will have long burrs.

Nylon Button Polish

When burrs cannot be removed using a nozzle separation machine, cold nitrogen air can be used to remove burrs.

Nylon Button Assemble

Nylon Finished Button

- Finished Button