产品

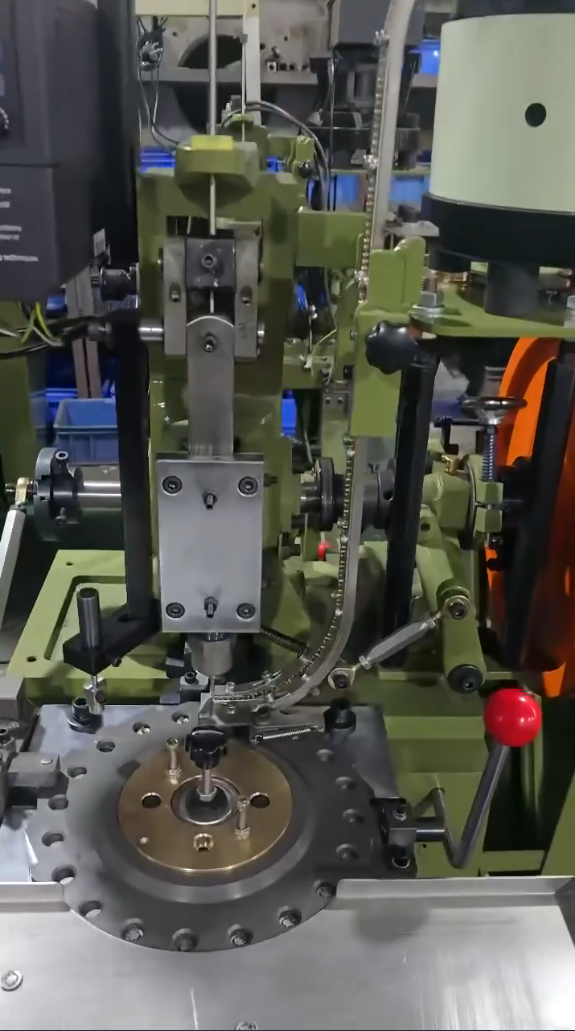

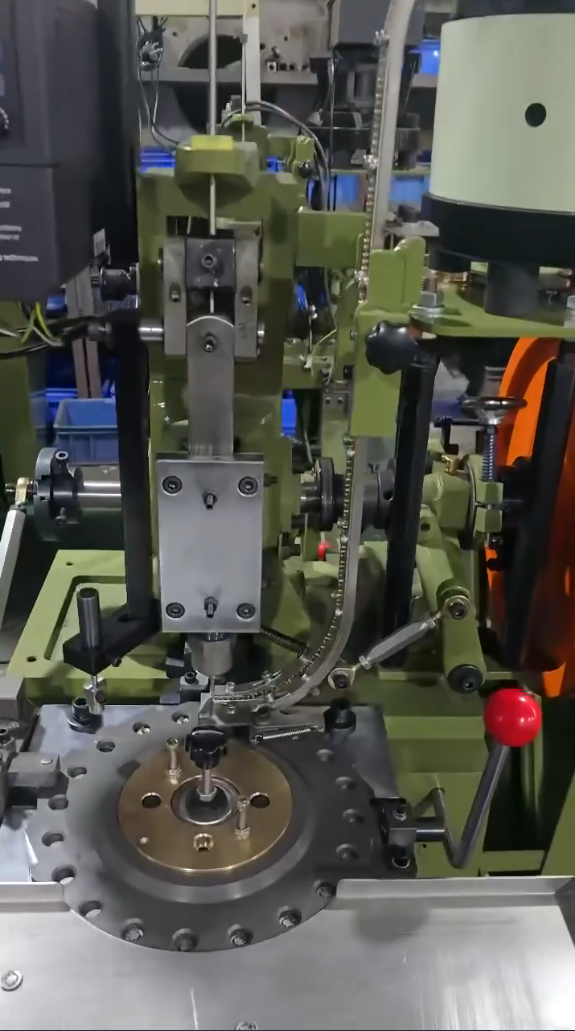

三合一按钮塑料和金属组装机

警告:foreach() 函数提供的参数无效 /www/wwwroot/qcgac.com/wp-content/themes/SNKJ/single/single-grid.php 在线的 196

产品结构

三元集成效率:一步完成三个组件的组装,与传统方法相比减少了 2-3 道工序,生产效率提高了 50% 以上,非常适合大订单。.

精确稳定的压制工艺**:采用数控压力系统和模具,确保组件对准精度在±0.1mm以内,从而形成牢固的结构,并最大限度地减少松动或错位等缺陷。.

材料兼容性强:可灵活组合塑料(ABS/PC)、金属(铜/不锈钢)、织物/树脂等材料,并通过更换模具快速切换按钮尺寸(直径 10-30 毫米)。.

显著的成本和效率优化:自动化取代了多工位人工,减少了301吨以上的人工成本;一体化设计节省了占地面积,简化了生产流程,降低了管理成本。.